About Sitro Group

Sitro has been a wholesaler and distributor of quality products to the outdoor leisure industry for over 20 years. Family owned and operated, Sitro is also involved in the design, development, and supply of products to major national retailers under their various own house branded products. Some of Sitro’s leading brands that are ordered by retailers are – Gasmate, Explore Planet Earth, Charmate, Broil King, AlfrescoPlus, MASTERBUILT, and Oklahoma Joe’s to name a few.

Continuing to be adaptable in a changing environment is one way they are achieving their mission and vision and in this instance that’s where PSIcapture comes in.

The Problem

Sitro receives hundreds of orders a day from their Australian retail partners. The ordering system was configured to automatically print each paper order to an output tray, which was subject to overflow during peak demand periods and when receiving unmonitored overnight orders. The existing process was antiquated and had outgrown itself. It was impacting the ability to provide a responsive and timely outcome for their customers.

As the Sitro network grew, warehouses were strategically sourced around Australia to provide a more effective delivery service to their retail partners. Sitro customer service staff were required to sort the physical orders by state-based warehouse location, then perform an auditing process to ensure all orders had been printed successfully. A secondary process followed to review all orders to ensure stock availability and adjustments made where required prior to warehouse operations taking place.

These tasks took time and were susceptible, even prone, to errors. Delays in the warehouses receiving the information they needed to perform their role of picking and shipping the goods were also attributable. These delays could impact the retailers’ sales when goods could not get to them in a timely fashion. Compounded by Covid-19 lockdown related issues such as lack of access to the physical printed orders and work environments Sitro embraced the necessary change.

The PSIGEN Solution

Sitro worked closely with the PSIGEN local reseller (Digital Document Solutions in Melbourne) and they were presented a solution that removes the need to print, manually sort and process physical paper.

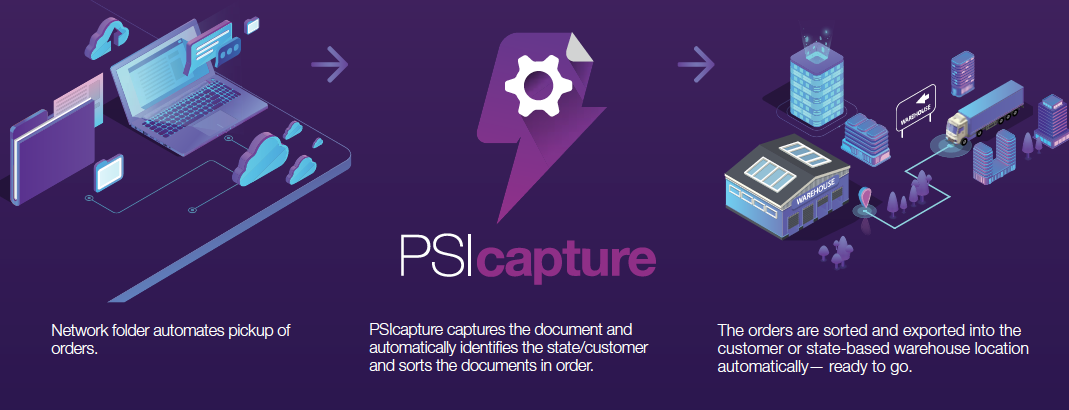

This is achieved by digitally capturing any orders that are received from their retail partners without the need for printing. A PSIcapture batch process is executed to automatically identify the customer and, based on the customer identity, it groups orders as required by Sitro.

As the process is now automated, PSIcapture has also been configured to send out communication alerts to the customer service team to notify them when specific customer orders have been processed and ready for review.

“The PSIcapture solution was able to achieve exactly what we were looking for and, with the advanced capture features that are available in the product, we are confident that we will be able to grow with the solution as our needs change” said Mr Mattia Ambrosi, Sitro Group IT Manager. “The implementation was very easy and delivered to our high expectation”

Results

No intervention or manual processing of the physical orders is needed by the Sitro staff members, and the warehouse locations get the information they need, without delay. The outcome has removed human error from the printing and sorting process, and it has reduced staff labour and printing costs via the removal of the need to print orders. The PSIcapture product provides a full audit trail and sends communication alerts of what orders have been processed and when.

Conclusion

Today, Sitro have peace of mind knowing that their retail partners’ orders are processed and audited to allow the warehouse locations to pick the stock without delay. They also have additional capacity and capability to meet seasonal demands on the ordering process and future growth aspirations.

“Sitro Group maintains its competitive advantage by implementing solutions that focus on improved quality and outcomes” said Mr Mattia Ambrosi, Sitro IT Manager. “By implementing the PSIcapture solution we have delivered not only internal focused outcomes, but it has had a direct positive improvement to our leading retail partners via the improvement to the backend ordering process.”

Solution Components in Summary:

Capture Software: PSIcapture

Document Import: Automated Network folder monitoring and processing for PDF’s

Document Export: Single PDF per warehouse location or by specific customer

Unleash the power of your people by eliminating data entry with business automation technology from PSIGEN. Implemented by a global network of integrators, PSIGEN paves the way for your digital transformation in four steps: on-ramp your information from paper and email attachments with PSIcapture advanced capture software; automate workflows with PSIsafe document management software; integrate these documents so they are available and searchable in software you use daily (ERP, CRM, HCM); and make better, decisions faster as a result – with a positive ROI in less than a month. Work the way you want, let technology do the rest. More: www.psigen.com